Streamlining Operations: How Roll-Up Door Machines Make Your Work Easy

Roll-up doors, which can be referred to as roller shutter doors, are quite important for various uses including households, garages, warehouses, and so forth, for the sake of ensuring both security and convenience. However, the procedure of producing these doorways in the past mainly relied on manual labor and time a lot. The introduction and use of roll-up door machines have transformed the process of handling inventories, making it faster and more convenient. This article throws light on how roller door machine makes your work simple and improves your productivity.

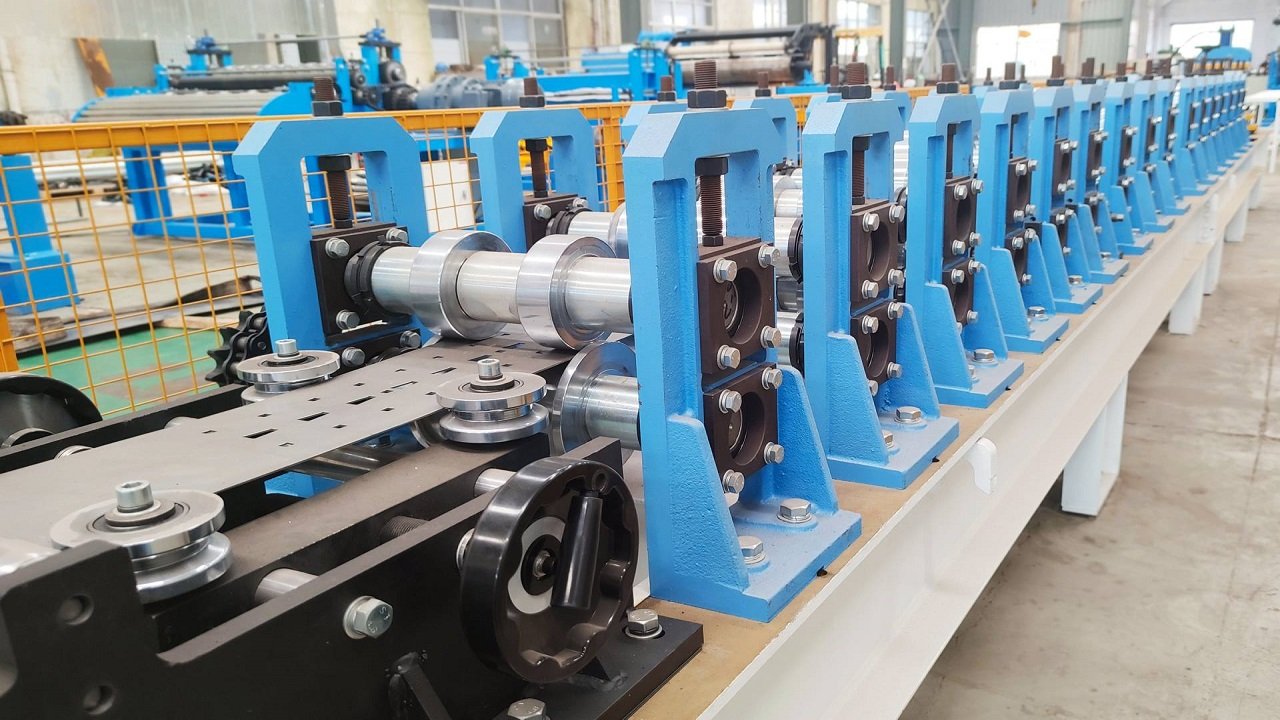

Automating Production with Roll Forming Machines

Being roll-forming machines that work as a clock of roll-up door assembly lines is the backbone of industries. In these machines, metal sheet shaping is done by automatic process, to obtain the desired profiles required for the roll-up doors. Through its ability to apply high-tech and exact controls to the manufacturing process, the roll-forming machine guarantees the uniformity of the dimensions and quality of the door pieces. This automation completely abates the process of cutting and shaping thus, reducing the time and cost of labor.

Seaming Machines for Seamless Integration

The seam-making machine is being found to be a vital tool to use when the construction process of the roll-up doors is being performed. Introducing this seamer to our production line, which seams the metal sheets fast and accurately, will only add to the quality of the doors as it will be able to assemble the metal sheets in a way that enhances the strength of the door. Automating the seam joining makes it possible to have identical and strong products, and at the same time, it reduces the number of factors that may lead to mistakes and scraps.

Customization Capabilities

In contrast to the conventional roll-up door machines, the contemporary roll-up door machines are not only capable of fulfilling but also surpassing the demands for customization since they are flexible. The vending machines are equipped with innovative technology that can change the length and width of their products, include specific features, or do something else to personalize the product to meet all consumer needs.

Enhanced Efficiency and Productivity

Unlike the manual involvement in the manufacturing process, this kind of equipment automates the production process, thus reducing the need for manual interference, and effectively increasing the efficiency and productivity of the manufacturing process. This assists manufacturers in their ability to fill orders with short-term deadlines as well as cope with large orders without the need for lengthy set-up times. Moreover, the manual work is easier and more accurate due to the automation, which in turn, reduces the downtime and scrap, and finally, the entire process is more cost-effective.

Conclusion

Roll-up door technology is today’s revolution in the production industry, as it simplifies and speeds up the whole process of manufacturing, as well as making it more efficient. From roll-forming machines that automatically change the shape of profiles to seaming machines that make a seamless connection, these technologies have transformed the process of roll-up door production. By their personalization ability and productivity, roll-up door machines not only help manufacturers work smarter but also produce items of higher quality that satisfy customers’ changing demands.